Surface Design Show 2024

in partnership with

Surface Design Show 2024

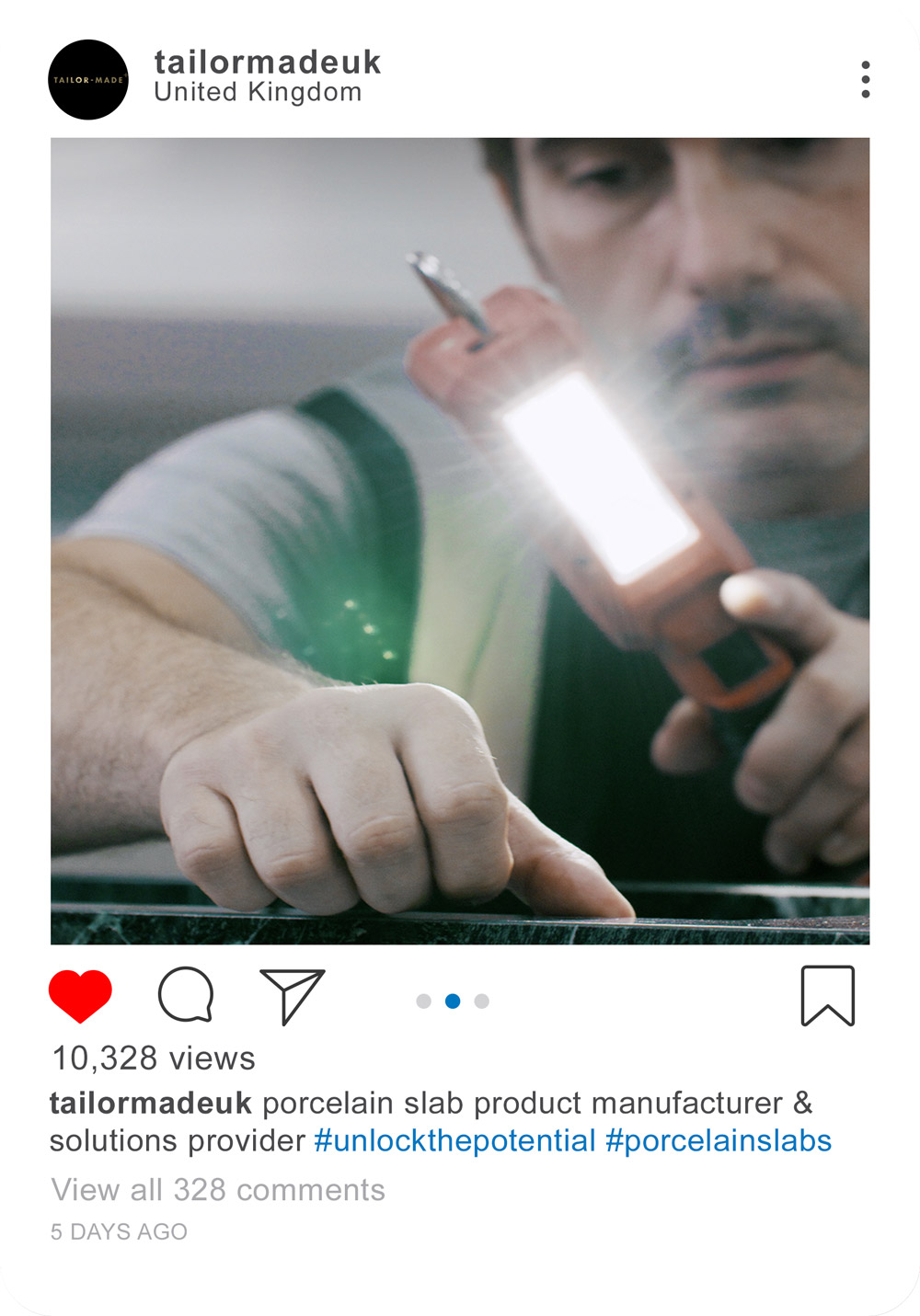

If you met with us at the Surface Design Show, we hope you enjoyed the exhibition and thank you for your time. You can view some photos from the show here. Large format porcelain slabs are one of the most sustainable and aesthetically appealing surface materials available today. The wider accessibility of this cutting-edge surface has transformed the way these materials are used, presenting new beginnings, new opportunities, and new challenges. To unlock the full potential of large format porcelain slabs, a comprehensive UK-based product manufacturer and solutions provider is essential. Tailor-made+ are that solution.

Cladding & boookmatching

Interior Products & Cut-to-size

Unlock the potential of the slab

We showcase products and cutting services designed to instil confidence in designers towards the progression from slab to surface. Services that redefine how designers approach material selection, providing design solutions for the functional and aesthetic requirements of each project. Services that facilitate the creation of luxury stand-alone products such as bathroom vanities, kitchen countertops and furniture. Services that assist designers to transform their ideas into completed products.

A deep understanding of porcelain stoneware and an eye for detail: we are proud to have created the most advanced, state-of-the-art design studio in the UK. There, a talent of architects, engineers, CAD technicians and account managers ensure that only the highest quality products, crafted to your exacting standards, are allowed to leave our studio.

Every item is carefully crafted, combining your creativity with the beauty of Italian porcelain stoneware. Each piece embodies the care and attention that only quality workmanship and a team of highly skilled technicians can provide. With exceptional quality in every detail from the perfectly mitred edges to the beautifully integrated surfaces, you can be confident that each element will be a visual delight, not only on the day they leave the studio, but for many years to come.

Who are these solutions for?

We support three core groups, interior designers, product manufacturers and professional contractors. We help designers to create bespoke interiors from stand-alone items to complete furnishing solutions. We enable furniture and design manufacturers to integrate porcelain surfaces into their products. And we supply pre-cut porcelain slabs and mitred panels to professional contractors, improving efficiency, reducing wastage and removing any risk of breakage onsite.

For interior designers there are no limits, create one-off pieces of furniture, kitchen islands and bathroom vanities from the finest Italian porcelain stoneware and provide your clients with an unlimited choice of bespoke options. Enjoy great craftsmanship with full manufacturing and installation support from an experienced UK based team.

Product manufacturers get to offer their clients the widest possible selection of over 150 colours and styles for tabletops, inlays, countertops, storage and media units. And with reliably short lead-times and the full support of our project managers and in-house templating and installation teams, these exciting opportunities come risk free to both you and your clients.

Professional contractors enjoy significantly reduced installation times through pre-cut slabs for flooring and surface covering. By receiving cut-to-size pieces supplied with 45° mitred edges, 3D cladding is stress-free with virtually no waste. Or for more complex installs, take advantage of our laser templating service for precision cut steps, staircases and circular seating.

Unified spaces and furniture inlays

Solutions

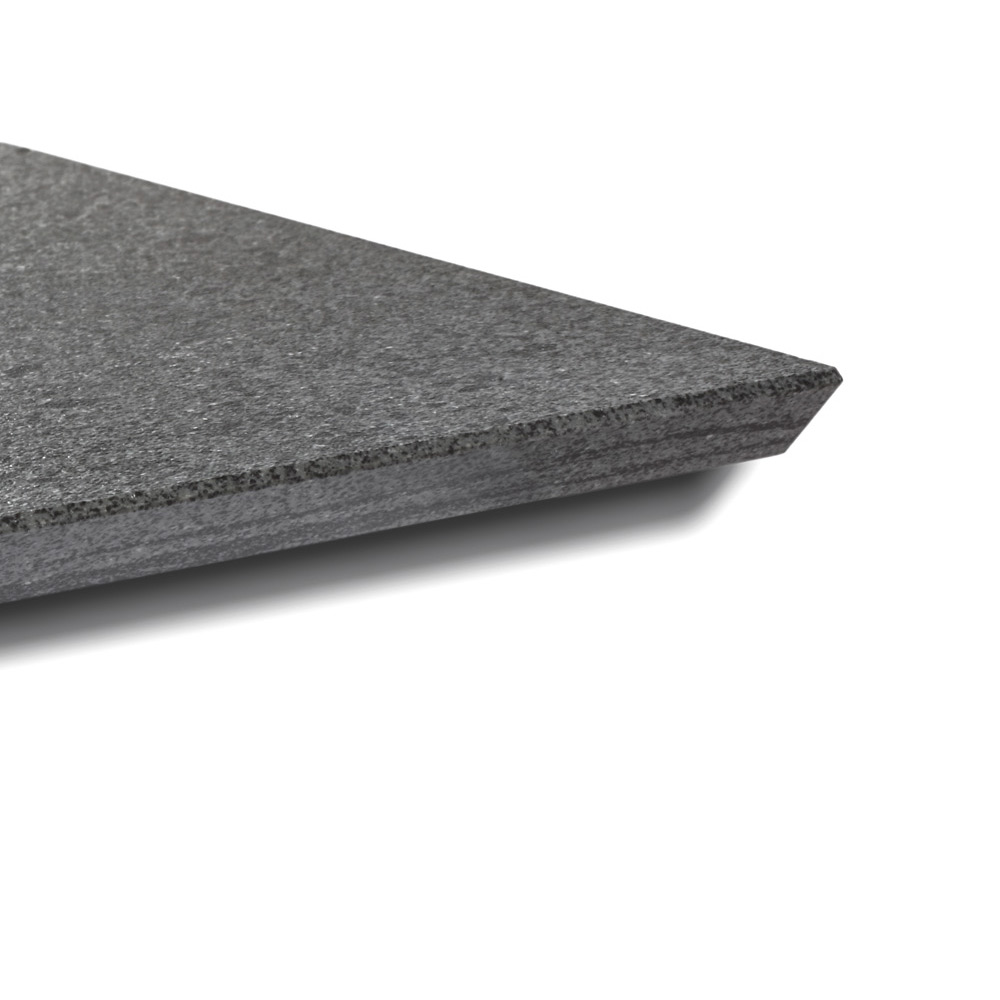

Porcelain slabs offer an extremely durable surface, but cutting and handling three-metre high formats onsite brings its own challenges, which can often result in chipping or cracking. By utilising our cut-to-size solution, the entire cutting process takes place offsite and is risk-free to you.

Cut-to-size

Cut-to-size eliminates the need for third- party operations including the transport of slabs between suppliers. Use cut- to-size for surface cladding, custom flooring, inlays and staircases. This level of support allows you to have a relaxed approach to specifying large formats and gives your installers the confidence to handle slabs onsite and complete projects successfully. It’s a collaboration that adds considerable value to a project, combining our expertise with your creativity, allowing this high- performingmaterialtobespecifiedwith confidence.

3D Cladding

Through the cut-to-size service we can supply pre-prepared 3D cladding for a whole host of practical, artistic, and time-saving applications. We meticulously label each piece and provide precision cut mitred edges for effortless installation. Employing pre- cut cladding streamlines the fabrication process, resulting in significant cost and time savings onsite. 3D cladding solutions can be used for residential projects both indoors and out, and for a host of retail and hospitality applications including plinths, planters, display stands, seating, and service counters.

Reimagine your cherished furniture pieces with the countless colour options and durability of a porcelain inlay or top. Upgrade your existing table tops and furniture inlays with precision cut-to-size porcelain surfaces, made possible by our advanced CNC cutting technology. We can accommodate any shape, including ovals, irregular shapes, or rectangles, and provide square or curved corners to your specification.

Vanities

Design stunning porcelain bathroom vanities, washbasins and storage units with creative freedom and the widest array of colour choices. All items are handcrafted and made-to-order empowering you to create unique and personalised bathroom designs, tailored to the exact requirements and technical specifications of your project.

Countertops

Using our solution, kitchen worktops, free-standing islands and waterfall island countertops can be specified in any style. They can be supplied pre-cut to fit an under-mounted basin or specifiedwithanintegratedsink,while matching splashbacks and cabinet fronts add to the possibilities.

We have collaborated with several designers to create a capsule range of products which demonstrate some of the possibilities that working with porcelain slabs provides. You can rely on our manufacturing expertise and technical support to design with freedom and unlock the full potential of the slab.

Colours

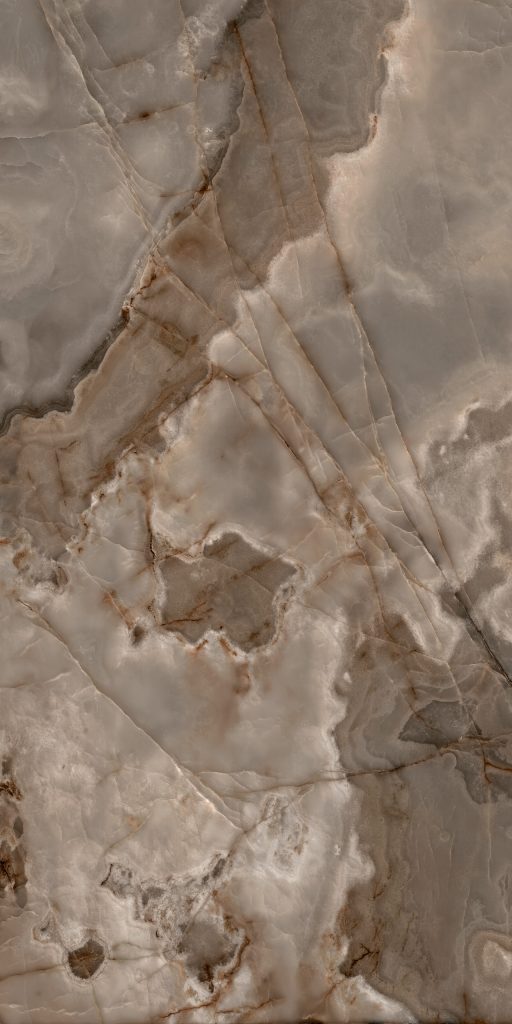

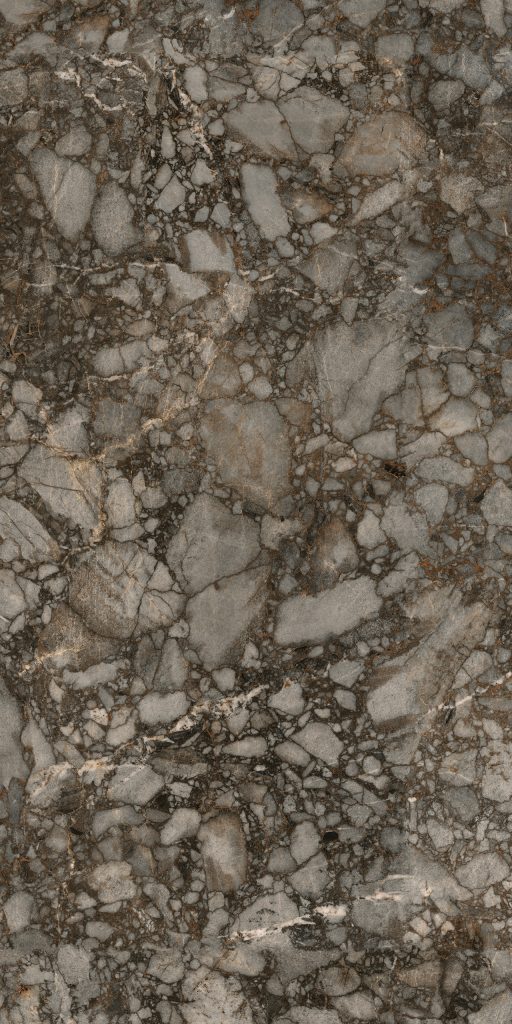

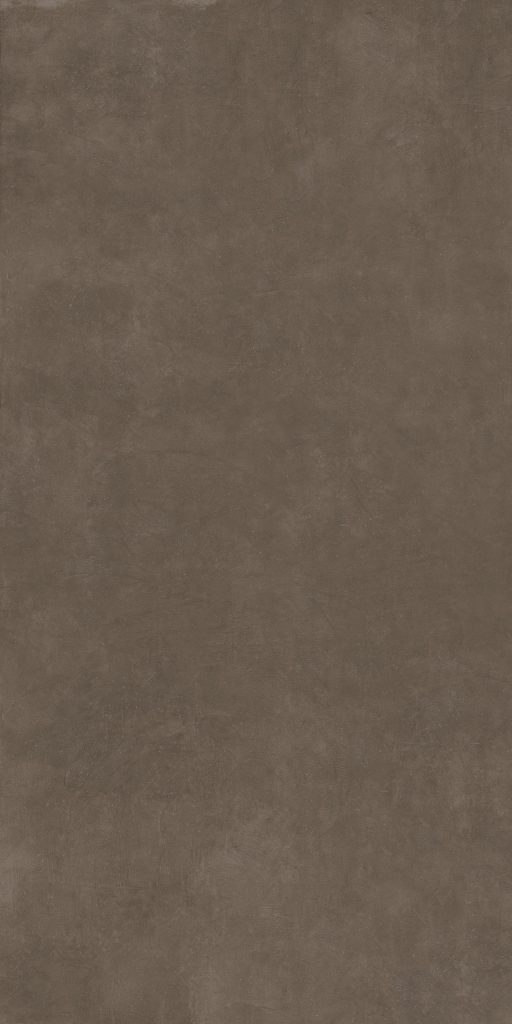

With a collection of over one hundred and fifty styles of marble, stone and concrete, the potential to push creative boundaries has never been more accessible. And with so many possibilities at their fingertips, designers have more freedom to follow their design principles and create unique concepts.

![]()

Onyx ![]()

Marble ![]()

Stone ![]()

Precious Stone ![]()

Concrete ![]()

Wood ![]()

Classic ![]()

Bookmatched

Finishes

Many of the surface coverings we provide are offered in a choice of finishes. Use the authenticity of Natural, the soft touch of Honed, or the spectacular elegance of Polished, to provide fine control over the visual impact and tactile feel your design.

Edge Profiles

Through our cut-to-shape service, many Tailor-made+ projects including countertops, furniture inlays, table tops and steps can access a choice of edge profiles. Whether to fulfil a practical requirement or chosen purely for their aesthetics, every profile is beautifully finished.

![Edge Profile - Straight Edge Profile - Straight]()

Straight Edge ![Edge Profile - Pencil Edge Profile - Pencil]()

Pencil Edge ![Edge Profile - Double Pencil Edge Profile - Double Pencil]()

Double Pencil Edge ![Edge Profile - Bevelled Edge Profile - Bevelled]()

Bevelled Edge ![Edge Profile - Double Bevelled Edge Profile - Double Bevelled]()

Double Bevelled Edge ![Edge Profile - Shark Nose Edge Profile - Shark Nose]()

Shark Nose Edge ![Edge Profile - Bullnose Edge Profile - Bullnose]()

Bullnose Edge ![Edge Profile - Half Bullnose Edge Edge Profile - Half Bullnose]()

Half Bullnose Edge

Made for the kitchen

Innovative, technically advanced and built to last, Italian porcelain stoneware has transformed kitchen design. By combining the widest selection of dramatic designs and textures, with the most durable and hygienic of surfaces, designers and architects can now deliver on performance, function and beauty.

Unlike many natural materials including wood, stone and marble, porcelain is entirely non-porous. This provides an extremely hygienic, anti-bacterial surface that is ideal for food preparation. It has a durable, non-scratch finish that is heat and blade resistant, and does not require sealing like granite or marble. The surface offers protection against mould and mildew that cause odours, while coffee, red wine or tomato based sauces will not stain and cleaning products are safe to use.

Kitchen countertops

Environmental Objectives

All our porcelain surfaces are manufactured using sustainable processes that minimise the impact on the environment, conserving both energy & natural resources.

All products are produced without the use of any harmful or radioactive materials, are free from pollutant emissions and will not effect air quality. All packing material is produced with recycled material. Wherever possible, heat generated as a by-product of the manufacturing process is used for electricity generation, making factories energy self sufficient. All waste material that is associated with the supply of the tile surface is fully recyclable.

All products are manufactured using materials from renewable sources. They have a reduced environmental impact throughout their lifespan and no toxic, harmful or polluting substances are used for their composition and production. The materials do not release toxic, harmful or polluting substances. All products meet the highest standards of quality and environmental regulations and conform to the following certifications:

| Environmental Certification | |

|---|---|

| LEED® certification provides independent, third party verification that a building project meets the highest green building and performance measure. All certified projects receive a LEED® plaque, which is nationally recognised symbol demonstrating that a building us environmentally responsible, profitable and a healthy place to live and work. The environmental characteristics have been evaluated and found according to the requirements of content of recycled material for environmental assessment according to LEED® criteria. These products contribute to the increase in the LEED® rating of buildings where they are used. | |

| The EU Ecolabel helps you identify products and services that have a reduced environmental impact throughout their life cycle, from the extraction of raw material through to production, use and disposal. Recognised throughout Europe, EU Ecolabel is a voluntary label promoting environmental excellence which can be trusted. Ecolabel certification applies to building products such as ceramic tiles for residential and public flooring and wall- covering. The commission in charge of the certification system measures the environmental impact caused by the entire productive cycle; in the case of ceramic tiles, the verification starts from raw material quarrying through to manufacturing, distribution, installation and their final disposal. Our factories conform and are certified by the European Community standard Ecolabel and the production process is in complete harmony with the Ecolabel certification. | |

| GREENGUARD Certification ensures that a product meets stringent standards for minimal emissions of volatile organic compounds (VOCs) into indoor air. This program provides assurance that products designed for indoor use adhere to strict chemical emissions limits, fostering the creation of healthier interiors. Manufacturers with GREENGUARD Certification gain credibility for their sustainability claims, supported by empirical technical data from an unbiased third-party organisation. The GREENGUARD Certification Program instills confidence by ensuring that indoor products meet strict chemical emissions limits, contributing to the creation of healthier interior spaces. This empowers manufacturers to produce and customers to identify products with low chemical emissions, thereby supporting air quality and environmental well-being. | |

| NSF® has facilitated the development of more than 75 standards and protocols for sanitary food equipment, and has certified thousands of products as safe to use in restaurant and commercial kitchen settings. NSF® food equipment standards include requirements for material safety, design, construction and product performance. The products conform to the requirements of NSF/ANSI Standard 51 – Food Equipment Materials. NSF/ANSI 51 establishes minimum public health and sanitation requirements for materials and finishes used in the manufacture of commercial foodservice equipment | |

More information?

For more information please complete the form below or contact us on 020 3848 5212 or email design@tailormade.uk

You can also follow us on instagram @tailormadeuk.

020 3848 5212

Monday to Friday: 9.00am – 5.00pm

020 3141 3337

Interior Design

Photos from Surface Design Show 2024

![Surface Design Show (Photo ID: 43940) Surface Design Show (Photo ID: 43940)]()

Surface Design Show Sds 2024 (Photo ID: 43940) ![Surface Design Show (Photo ID: 43941) Surface Design Show (Photo ID: 43941)]()

Surface Design Show Sds 2024 (Photo ID: 43941) ![Surface Design Show (Photo ID: 43942) Surface Design Show (Photo ID: 43942)]()

Surface Design Show Sds 2024 (Photo ID: 43942) ![Surface Design Show (Photo ID: 43944) Surface Design Show (Photo ID: 43944)]()

Surface Design Show Sds 2024 (Photo ID: 43944) ![Surface Design Show (Photo ID: 43946) Surface Design Show (Photo ID: 43946)]()

Surface Design Show Sds 2024 (Photo ID: 43946) ![Surface Design Show (Photo ID: 43947) Surface Design Show (Photo ID: 43947)]()

Surface Design Show Sds 2024 (Photo ID: 43947) ![Surface Design Show (Photo ID: 43948) Surface Design Show (Photo ID: 43948)]()

Surface Design Show Sds 2024 (Photo ID: 43948) ![Surface Design Show (Photo ID: 43949) Surface Design Show (Photo ID: 43949)]()

Surface Design Show Sds 2024 (Photo ID: 43949) ![Surface Design Show (Photo ID: 43951) Surface Design Show (Photo ID: 43951)]()

Surface Design Show Sds 2024 (Photo ID: 43951) ![Surface Design Show (Photo ID: 43952) Surface Design Show (Photo ID: 43952)]()

Surface Design Show Sds 2024 (Photo ID: 43952) ![Surface Design Show (Photo ID: 43953) Surface Design Show (Photo ID: 43953)]()

Surface Design Show Sds 2024 (Photo ID: 43953) ![Surface Design Show (Photo ID: 43954) Surface Design Show (Photo ID: 43954)]()

Surface Design Show Sds 2024 (Photo ID: 43954) ![Surface Design Show (Photo ID: 43955) Surface Design Show (Photo ID: 43955)]()

Surface Design Show Sds 2024 (Photo ID: 43955) ![Surface Design Show (Photo ID: 43956) Surface Design Show (Photo ID: 43956)]()

Surface Design Show Sds 2024 (Photo ID: 43956) ![Surface Design Show (Photo ID: 43957) Surface Design Show (Photo ID: 43957)]()

Surface Design Show Sds 2024 (Photo ID: 43957) ![Surface Design Show (Photo ID: 43958) Surface Design Show (Photo ID: 43958)]()

Surface Design Show Sds 2024 (Photo ID: 43958) ![Surface Design Show (Photo ID: 43959) Surface Design Show (Photo ID: 43959)]()

Surface Design Show Sds 2024 (Photo ID: 43959) ![Surface Design Show (Photo ID: 43961) Surface Design Show (Photo ID: 43961)]()

Surface Design Show Sds 2024 (Photo ID: 43961) ![Surface Design Show (Photo ID: 43962) Surface Design Show (Photo ID: 43962)]()

Surface Design Show Sds 2024 (Photo ID: 43962) ![Surface Design Show (Photo ID: 43964) Surface Design Show (Photo ID: 43964)]()

Surface Design Show Sds 2024 (Photo ID: 43964) ![Surface Design Show (Photo ID: 43966) Surface Design Show (Photo ID: 43966)]()

Surface Design Show Sds 2024 (Photo ID: 43966)

- Surface Design Show (Photo ID: 43940)

- Surface Design Show (Photo ID: 43941)

- Surface Design Show (Photo ID: 43942)

- Surface Design Show (Photo ID: 43944)

- Surface Design Show (Photo ID: 43946)

- Surface Design Show (Photo ID: 43947)

- Surface Design Show (Photo ID: 43948)

- Surface Design Show (Photo ID: 43949)

- Surface Design Show (Photo ID: 43951)

- Surface Design Show (Photo ID: 43952)

- Surface Design Show (Photo ID: 43953)

- Surface Design Show (Photo ID: 43954)

- Surface Design Show (Photo ID: 43955)

- Surface Design Show (Photo ID: 43956)

- Surface Design Show (Photo ID: 43957)

- Surface Design Show (Photo ID: 43958)

- Surface Design Show (Photo ID: 43959)

- Surface Design Show (Photo ID: 43961)

- Surface Design Show (Photo ID: 43962)

- Surface Design Show (Photo ID: 43964)

- Surface Design Show (Photo ID: 43966)